Deciding to use corn syrup vs. sugar in certain recipes can be a head-scratcher. If they both act as sweetening agents then what's the difference really? While corn syrup is made by breaking down the chemical composition of starchy foods, sugar is a crystalline form of the compound that naturally sweetens fruits, milk, and vegetables. We'll get more into the details of each in a moment.

One major difference between the two is the fact that there are far more types of sugar than processed versions of corn syrup. Corn syrup is just that, a syrup, while sugar, no matter the type, does typically get processed into a crystalline form of some kind. Use either one in recipes for sweetening, however, you need to pay close attention to the ways that syrup will affect the consistency of a recipe versus granulated or other types of solid sugar. Let's get into the interesting facts behind what makes corn syrup vs. sugar so unique.

In this post, we'll discuss the histories and processes for developing both products. You'll learn some of the most popular ways in which they are used and get some ideas of your own for which one to pick. We'll talk about the types of sugar available to choose from, and by the end of this, you'll have a better understanding of which one of these options, corn syrup vs. sugar, best fits your sweetening needs.

Corn Syrup vs. Sugar: What is the Difference?

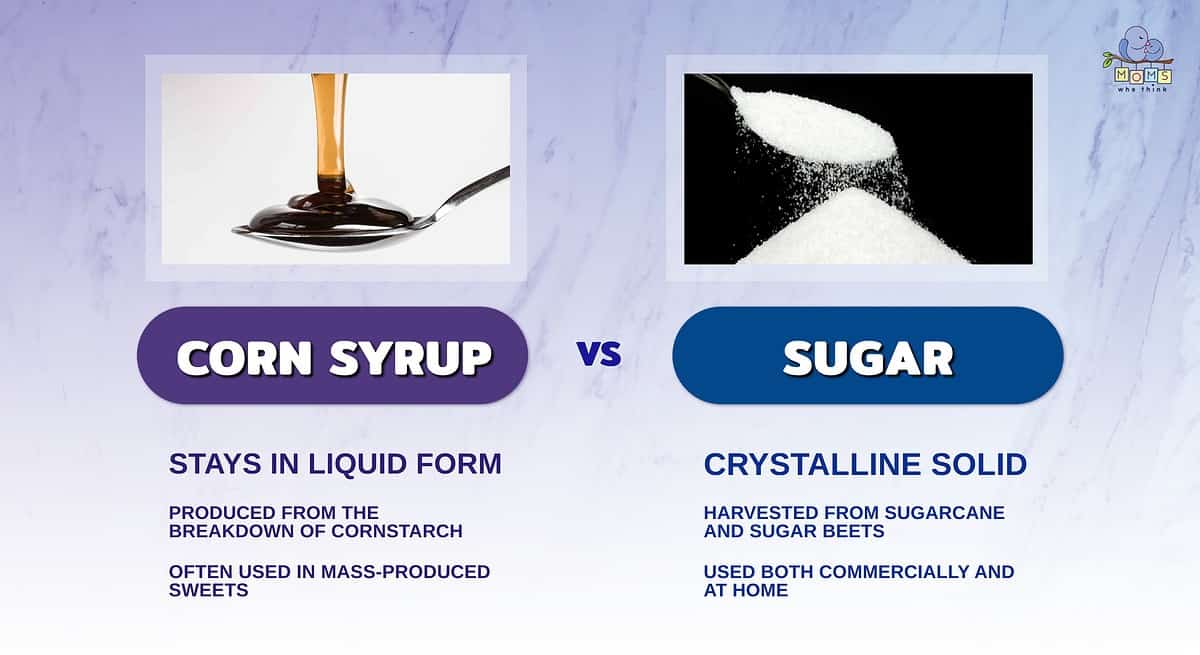

Corn syrup is the result of breaking down starch-containing foods into a chemical compound that acts as a natural sweetener. It stays in its liquid form and does not crystallize. Sugar, on the other hand, is a water-soluble compound that is harvested from sugar cane and sugar beets. Sugar is sold in refined and unrefined forms. It is a crystalline solid that can come in many shades of white, tan, and brown.

What is Corn Syrup?

Corn syrup is a syrup produced from the breakdown of cornstarch. Its close cousin, glucose syrup can be created from other starchy foods including wheat, rice, cassava, and potatoes can also be used to create this vicious type of sweetener. In this process, glucose molecules are broken down in the process of hydrolyzing starch, which results in glucose-based syrup. Corn syrup can be concentrated into a solid, similar to a stevia sweetening powder (via Healthline).

History And Origin of Corn Syrup

Corn is a staple crop in many cultures and parts of the world. Its widespread popularity encouraged farmers, inventors, and businessmen alike to find the best, most efficient ways to process all parts of this crop. Initially, hydraulic (water-powered) mills, were used to grind dried corn. In the 1700s, a device was invented to shell dried corn kernels. Wet milling was invented soon after, which enabled the separation of the corn meat from the starch.

The process of converting starch into sugar was actually invented in Japan during the 800s. It was rediscovered in 1811 by a Russian chemist named G.S.C. Kirchoff. By combining potato starch in a heated solution with sulfuric acid, the breakdown resulted in starch-derived sugars. In the States, an acid-conversion method was used in a plant in Buffalo, NY to create starch-based sugars. This remained the principal method for starch-sugar production until 1967 when another method for adding enzymes to break down glucose was commercialized. From there, the corn syrup industry boomed, partly because it was much more affordable than other types of sugar (via Encylopedia.com).

How Corn Syrup is Made

We touched briefly on the two popular methods for corn syrup production above, but let's get into the specifics. As described by Science Direct, corn syrup, is made through the process of hydrolyzing a mixture of starch concentrate with water. Enzymes are added and through a heating, and cooling process, the starch breaks down into a sweet concentrate with a high glucose sugar content. After this, the resulting corn syrup is further processed, decolorized, and bottled. Dark corn syrup is not decolorized, and molasses is added to give it a dark color and more intense flavoring.

Popular Uses

Commercially, corn syrup is advertised for its thickening and sweetening properties. It is much cheaper than other forms of sugar and therefore is used often in soft drinks, jams, jellies, and other mass-produced sugary items. It is also good for retaining moisture and thus can be used for baking projects. Try it out in pies, on popcorn, or in homemade candy. It is also used in the production of ice creams and other creamy desserts.

What is Sugar?

Sugar is a crystalline, processed version of evaporated sugar cane or sugar beet juice. The types of sugar are dependent on the cleaning, and crystallization process. For instance, brown sugar is a result of molasses being added to the boiling sugar mixture before it dries. The major classes of sugar include white sugars (granulated, confectioners, fruit sugar), brown sugars (turbinado, muscovado, jaggery), and liquid sugars (simple syrups).

History and Origin of Sugar

The first traces of the sugar cane crop date back to 8,000 BCE in New Guinea. There are records of it being used medically throughout early Roman and Greek civilizations. Around this time the methods for harvesting and processing sugar spread throughout Persia, and from there to all their trade routes. Conquering and exploration throughout the 11th century brought sugar to parts of North Africa and major cities in Europe.

By the 13th century, sugar presses were developed to increase juice production. From this juice, the evaporated crystalline sugar was formed. Sugar cane plantations began to populate warm climates, and in 1747, a German Chemist by the name of Andreas Marggraf identified sugar beets. This finding allowed for further sugar production from a crop outside of just sugar cane. From there, the sugar industry expanded and evolved to fit the needs of the world's dependency on the sweetness of sugar (via The Sugar Association).

How Sugar is Processed

The short version of sugar production is that whether the sugar juice comes from beets or cane, it goes through a few major steps in processing. These steps are juice extraction, clarification (heat and acid are added), concentration, crystallization, and finally, separation and drying. Refined sugar goes through a process of washing, dissolution, further clarification, and de-coloration before being crystallized. Unrefined sugars may add molasses or caramel coloring to the heated mixture before it crystallizes. This results in brown, larger sugar crystals. There are many ways to modify and process sugars (via Brittanica).

Nutritional Value

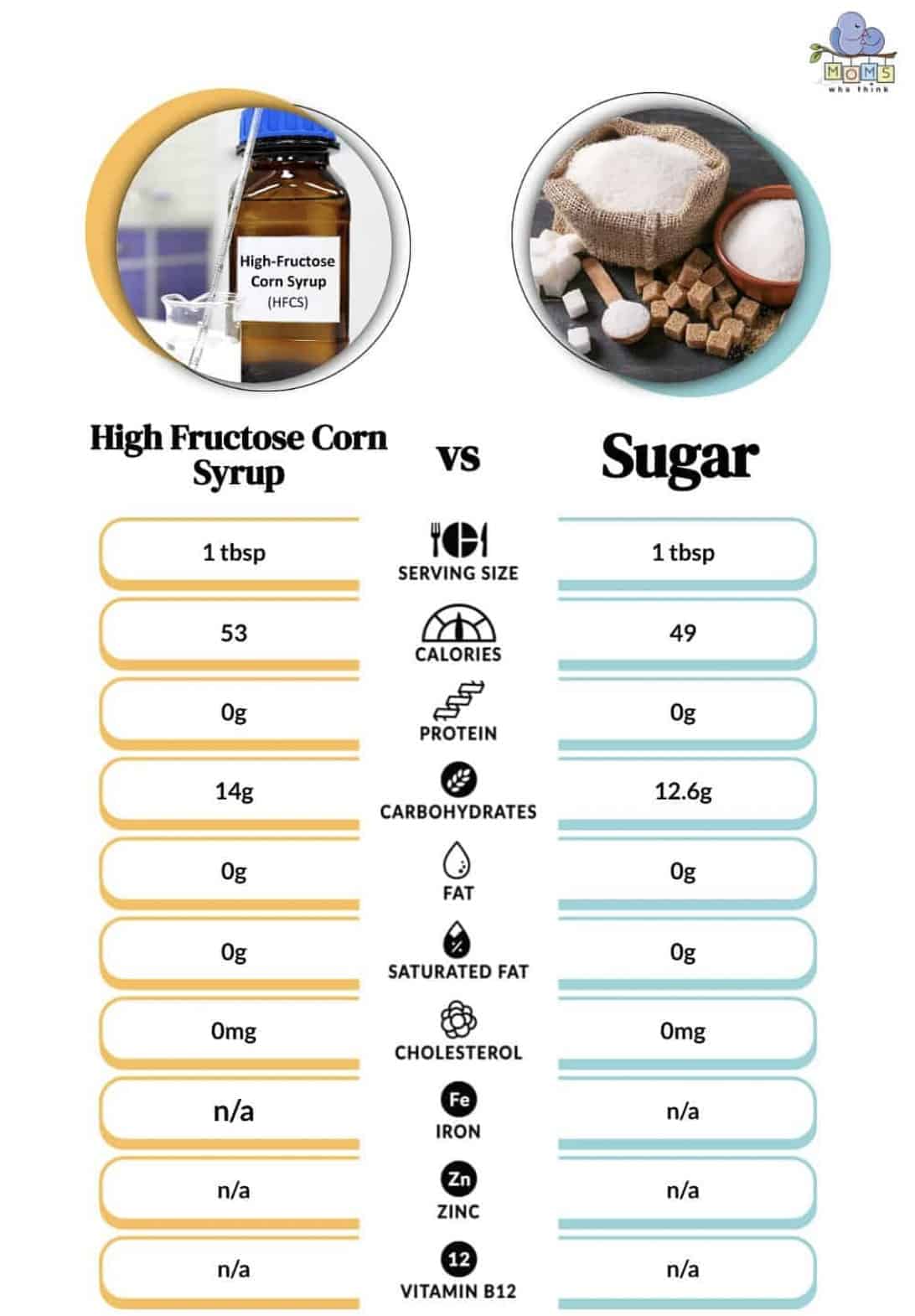

While there are not many health benefits to either of these types of sweeteners, they are both fine in moderation. As you'll see from the chart below, a tablespoon of each sweetener has a similar calorie content and carbohydrate content. There's not much more to them beyond calories and carbs!

Possible Alternatives to Corn Syrup or Sugar

For alternative sweeteners to corn syrup and/or crystalline sugar, check out honey, molasses, monk fruit, stevia, or maple syrup. If you're substituting using any of these, keep in mind the ratios of taste and sweetening. Honey is sweeter than corn syrup, so you'll need less of it. Just as you need to adjust using a syrup sweetener compared to how many cups of crystalline sugar you'll use in a cake!

Corn Syrup vs. Sugar: Are They The Same Thing?

- Corn syrup stays in a liquid form, while sugar is a crystalline solid. Both sweeteners can come in a variety of colors.

- Corn syrup is produced from the breakdown of cornstarch, while sugar is harvested from sugarcane and sugar beets. This difference may make corn syrup seem more artificial to you, but both products have natural sources.

- Because of its affordability, corn syrup is often used as a sweetener in mass-produced sweets. Sugar is used both commercially and at home.

In short, the answer to this question is no. When comparing corn syrup vs. sugar, they are not the same thing. They are, however, comparable ingredients. Corn syrup is a concentrated syrup that comes from breaking down the glucose in corn starch. Sugar comes from the sugar found in sugar cane and sugar beet juice. This juice is then processed to be dried for crystallizing. Corn syrup and sugar can both be used as sweeteners, but they have characteristics and properties that are different enough to affect the way they are used in certain recipes.

Interested in trying a new sweet treat? Take a look at this peach pie recipe:

Print

Peach Pie

Ingredients

- 2 pie crusts, unbaked (recipe here)

- 6 medium peaches

- 1/3 cup flour

- 1 cup sugar

- pinch salt

- 1 teaspoon lemon juice

Instructions

1. Preheat oven to 350 degrees Fahrenheit.

2. Wash peaches, remove the seed, then peel and slice.

2. In a large bowl, combine sliced peaches, sugar, flour, salt, and lemon juice.

3. Pour the mixture into a prepared pie crust, and dot the top of the peaches with a little butter.

4. Place the top crust onto the peaches in the pie pan. Seal the edges, then cut a few slits in the top of the pie crust to let steam escape.

5. Sprinkle some sugar on the top of the pie crust.

6. Bake for 35-45 minutes.

The image featured at the top of this post is ©iStock.com/Avtor.